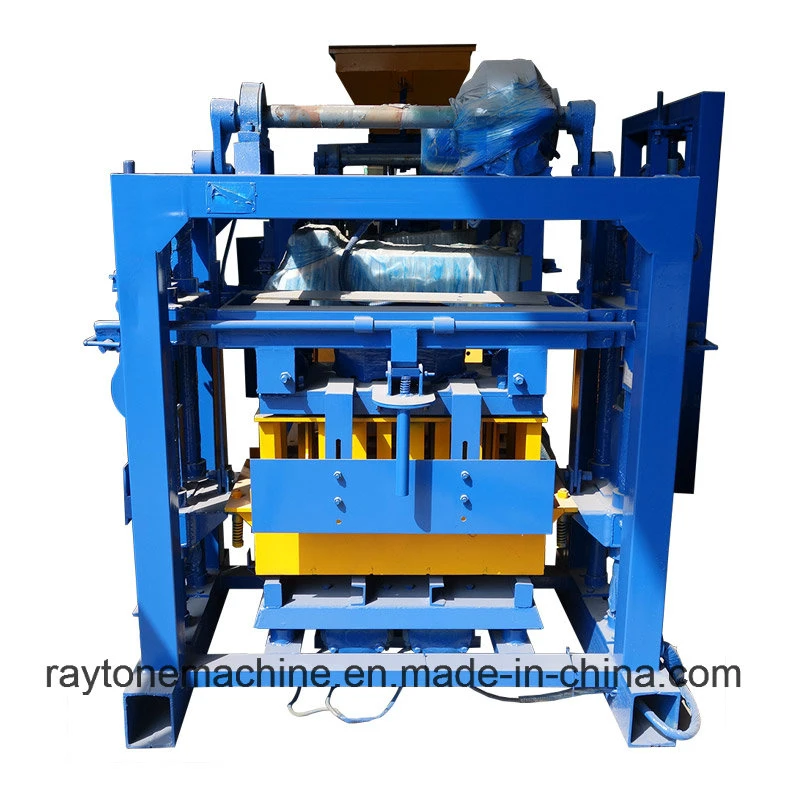

QT40-2 cement and cinder manual interlock block making machine

Product Description

Introduction of interlocking block making machine:

QT40 -2 type block machine is created based on original block molding machine with technological innovation and development, Its design is reasonable, excellent performance, This machine equipped with super vibration motor. The production of blocks are of good quality, large density and high strength. adopting manual push-pull mold, artificially packing material, simple operation, save energy, finished brick faster, low labor intensity.

Main technical parameters

Theoretical productive capacity

Production process

Raw Material proportion:

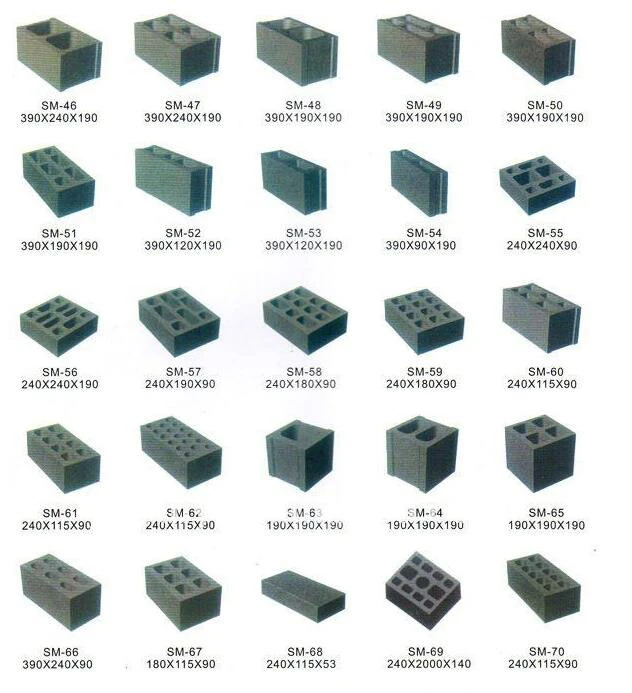

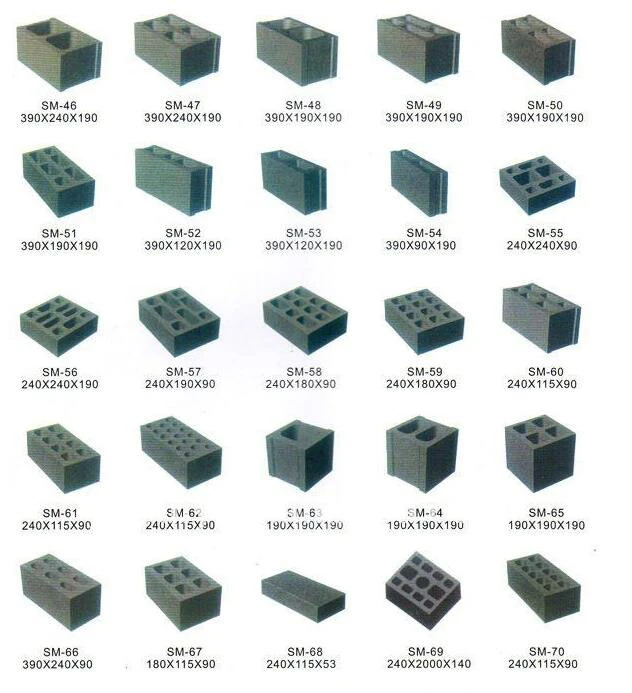

Block samples

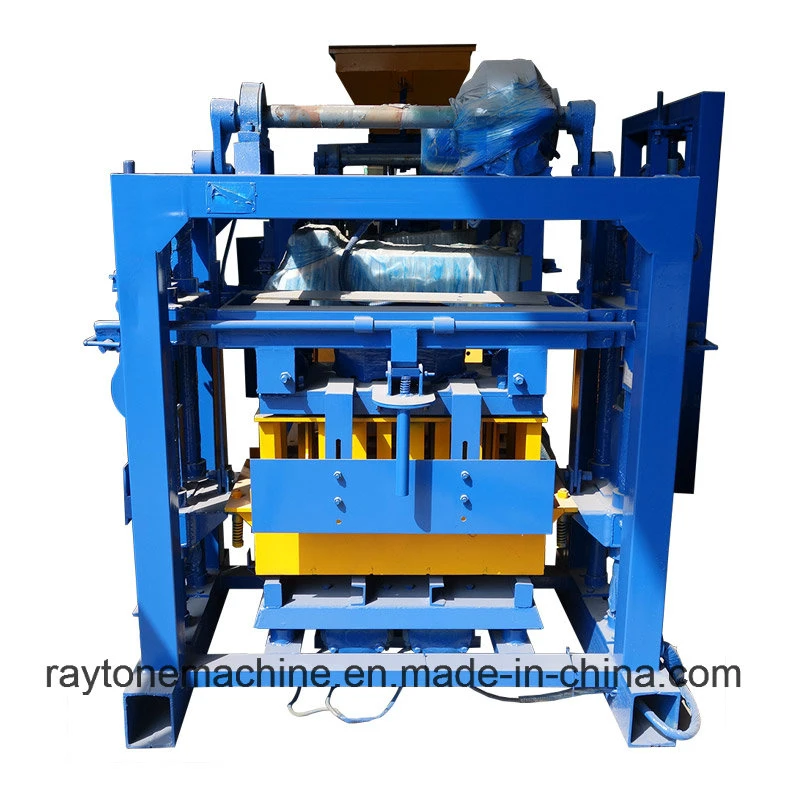

JQ 350 Mixer

Product Description

Introduction of interlocking block making machine:

QT40 -2 type block machine is created based on original block molding machine with technological innovation and development, Its design is reasonable, excellent performance, This machine equipped with super vibration motor. The production of blocks are of good quality, large density and high strength. adopting manual push-pull mold, artificially packing material, simple operation, save energy, finished brick faster, low labor intensity.

Main technical parameters

| Dimension of host machine | 1350×1460×1800mm | Host Machine Power | 8.8KW | |

| Voltage | 380V or adapt to your local voltage | Vibration Force | 30KN | |

| Moulding peiod | 40S | Capacity | 16.3KW | |

| The size of the pallet | 850×450×30mm | Mixer Model | JQ350 | |

| Weight of the machine | About 1.8T | Workshop Area | 60m2 |

Theoretical productive capacity

| Size(LxWxH) | Pcs/Mould | Pcs/ 8 Hr |

| 400X150X200 | 5 | 3000 |

| 400X200X200 | 4 | 2600 |

Raw Material proportion:

1. 8%-10% cement ,30%-40% sand, 50%-60% stone(less than 15mm)

2. 8% cement,60% sand,Fly ash 30%,2% gypsum

Moulds2. 8% cement,60% sand,Fly ash 30%,2% gypsum

Block samples

JQ 350 Mixer

ANY QUESTIONS, PLS FEEL FREE TO CONTACT US!